- Home

- Filter Revamping and Upgrading

- Customers we served

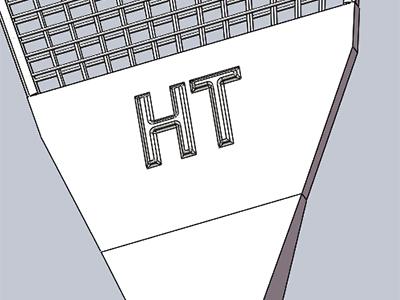

- Vacuum disc filter upgrading for INDAH

Modification for 108 sets of sectors including the mesh screens. The main material of sectors was SS304, and the material of the mesh screen was PP.

Modification for cleaning system: one set, SS304 material

The debugging of equipment processing was normal, which should meet the following technical indicators

Whitewater processing capacity: 12000 lpm

SS level of super-clear filtrate: ≤100 ppm

SS level of clear filtrate: ≤150 ppm

SS level of cloudy filtrate: ≤350 ppm

Hengtai guides the process, control and equipment commissioning, and provides guidance for standard operation of equipment and staff training.

The users are response for the field instrument of the disc filter and control system.

In addition to the modified sectors and cleaning system, the other spare parts are not within the scope of the quotation.

Current operating equipment and process parametersOriginal manufacturer: ANDRITZ

Number of devices: 2 sets

Application: Pulp fiber recycling

Model: DF57×8

Disc diameters: 5700 mm

Sector area per disc: 40 m2

Disc: 8

Number of sectors per disc: 18

Number of discs installed: 5

It is required to modify one device in processing, and the other one that has been shut down is temporarily not modified. The number of the disc of sectors should increase by one to reach 6 discs.

Pulp freeness: 350 CSF

Ash content: ≤18%

Discs space: 350

Concentration of whitewater: 0.2 %

pH: 6-8

Temperature: 40-45°C

Current equipment operation: The equipment is in an abnormal operating state.

- The sectors are seriously deformed

According to the analysis by our company technical staff, there are two main reasons that leading the sectors are seriously deformed. Firstly, the rigidity of sectors designed by the original company is not enough. Secondly, the equipment operation training of original company is not in place, the key process operation is not operated properly. - The bracket of cleaning system is easily broken

The main reason is that the cleaning system structure of the original company is unreasonable. A bracket is damaged, resulting in the scrapping of the entire cleaning system. - The SS level of filtrate is high

The main reason is that the sector seals of the connection between the center shaft and sectors are seriously deformed, resulting in pulp leakage to the filtrate.

In order to improve the reliability of the equipment, improve the operation effect of the disc filter, and reduce the maintenance costs, we redesign the structure of sector, cleaning system and sector seal without changing the overall structure of the equipment, and try to minimize modification costs.

After the discussion between our R&D team and the production team, the main idea is to modify the structure or the material of the sectors, brackets, top strap and other spare parts.

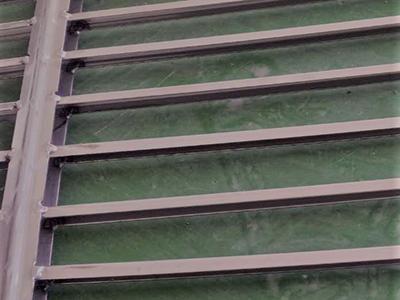

SectorSector grid

The original sector grid is a U-shaped structure made of 1 mm stainless steel, which displays weak rigidity. In order to increase the rigidity of the sector grid, we apply other structures of sector grid by using flat steel (3×14 mm) welded with the φ3 round bar steel, which greatly improved the rigidity of sector grid. The comparison structure is as follows:-

Sector bracket

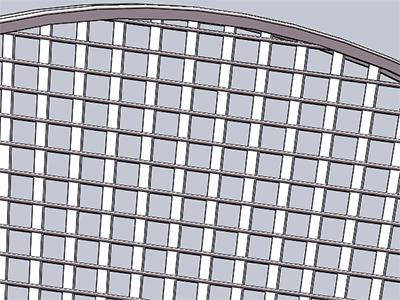

The original structure of the sector bracket displays a square planar structure welded with a 1mm stainless steel with poor rigidity. In order to increase the rigidity, we apply a curved structure made of 2.5 mm stainless steel, which greatly increases the rigidity of the bracket. The new structure is shown in the figure. -

Sector chute

The original structure of the sector chute displays a planar structure, and the rigidity of the planar structure is poor. In order to increase the rigidity and prevent the installation of the center shaft from being affected, we installed a saddle structure on the sector chute without changing the original size of sector chute. The comparison figures are as follows: -

Strap on the top of the sector

The original structure of strap is a U-structure made of 1 mm stainless steel plate, which displays poor rigidity. The new structure applies a 2 mm double U-shaped structure and the rigidity is increased by 5 times. The comparison figures are as follows:The shapes of the entire sector and sector bracket and the installation dimensions are completely consistent with the original structure, thus ensuring the reliability. In order to match the center shaft precisely, we maintains 18 sectors for one disc, and the structural diameter of the entire sector is 5700 mm, thereby ensuring that the installation of the disc filter does not present any risk.

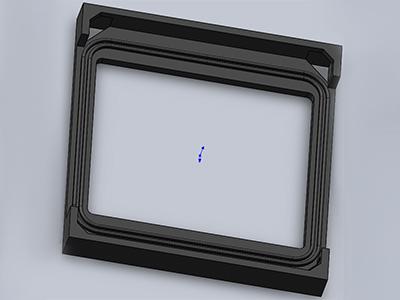

Replacement of sector seal

In order to ensure the quality of the SS level after the equipment installation, we modified the internal structure of the sector seal without changing the original size of the sector seals so as to solve the deformation problems of original sector seals. The deformation problems of original sector seals are shown in the figure:

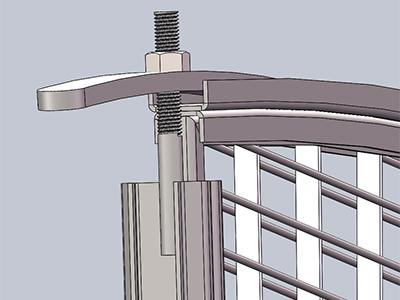

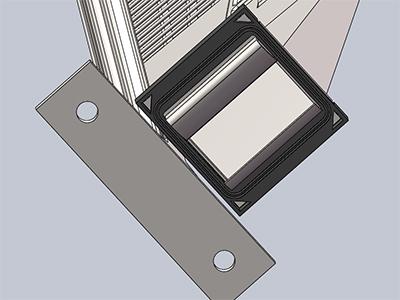

Cleaning system bracket

The current connection of cleaning system bracket is one kind of non-detachable connection, welded connection. Once a problem occurs, it will lead to fatal consequences, resulting in that the entire cleaning system cannot be used. We redesign the cleaning system equipment with a detachable cleaning system bracket (As shown in the figure below). When the cleaning system bracket is broken, we can remove and replace the new spare parts, thus greatly reducing the cost of equipment maintenance.

USA - Choose Country

USA - Choose Country