- Home

- Filter Revamping and Upgrading

- Customers we served

- Rotary drum vacuum filter modification for Liansheng Paper

Filter equipment number: 4 sets.

Three models of vacuum disc filter: 1 set ZNH35, 2 sets ZNH45, 1 set ZNH25.

ZNH35: A disc consists of 14 sectors

ZNH45: A disc consists of 16 sectors

ZNH25: A disc consists of 12 sectors

Problems

From the on-site inspection, there was a great deal of dislocation visible to the naked eye between the sector bottom and the sector base. After a careful analysis by the technical team, the conclusion was the pulp leakage was caused by serious design defects at the interface between the sector and the sector base.

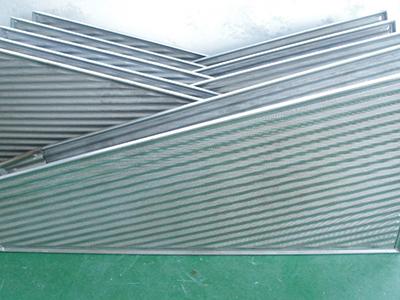

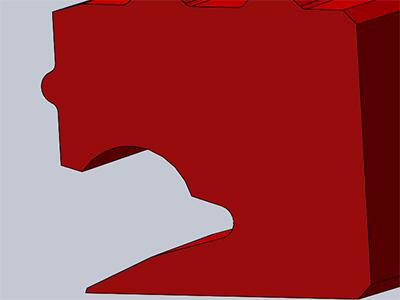

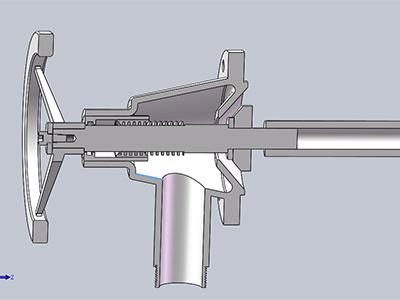

The sector base from the original company is shown in the following figure.

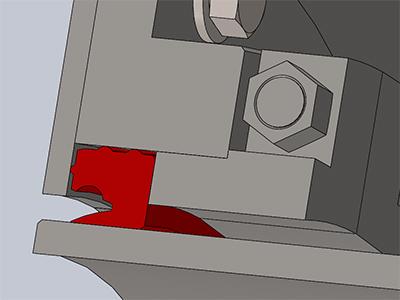

The schematic structure of the dislocation between the sector bottom and the sector base is shown in the following figure.

One of the main problems was the discovery that the sealing surface of the sector base was too small, and there was no limit structure for the sector base and the sector. During installation, the sector was not easy to locate, but was easy to dislocate, leading to the sector bottom falling off the sector base. This lead to a large amount of fiber leaking away from the dislocation joint surface to the clear filtrate and cloudy filtrate tanks. Since the clear filtrate was used for cake discharging and cleaning, too much fiber and filler leaked into the clear filtrate, resulting in a vicious circle, such as the blocking of the spray nozzles. When this happened, the mesh screen could not be completely cleaned, which caused serious problems, as the pulp cake could not be discharged.

These two problems had a significant amount of impact on the process parameter performance, leading to a reduced reliability and high maintenance and repair costs.

Solutions

In order to improve the reliability of the equipment, improve the operation effect of the disc filter, and reduce the maintenance costs, we redesigned the sector base structure, without having to change the overall equipment structure, and minimized modification costs.

The main idea was to modify the sector base without changing the sector structure, and increase the sealing surface to improve the sealing performance.

We redesigned the sector base structure without changing the original sector base connection size. The new sector base structure is shown in the following figure.The advantages of this solution: the structural size of the equipment will not be changed, the sealing problem was solved, the pulp leakage problem caused by the dislocation was solved, the cleaning and cake discharging function was restored, the equipment operated normally, and the process parameters of the equipment were greatly improved, and modification costs were low.

The installation diagram of the new structure sector plate and the base are shown as follows:Problems

The installation position of disc filter was relatively high, the operating temperature was high, and the operating environment was quite poor. The operator was unable to stay too long near the disc filter, and it was difficult to replace the filter cloth, as the customer could not find the broken filter cloth.

Solutions

We replaced the original sector with a non-filter cloth sector. After replacement, the filter area of sector increased by 15%, thus the output was also increased. The SS level of the filtrate was also greatly improved, which brought about significant economic benefits. The labor intensity of the operators was greatly reduced, and the maintenance costs were also reduced.

Problems

The strength and rigidity of the sector top connection plate manufactured by the original manufacturer were not enough, and the sectors fell off to easily, resulting in entire sections of the disc sectors breaking and huge losses.

Solutions

In order to increase the equipment reliability, we redesigned the structure of the connecting plate according to the problems of original structure. After modification, the strength and rigidity of the connecting plate increased. The replacement was convenient and fast, and the sector was well protected.

Problem

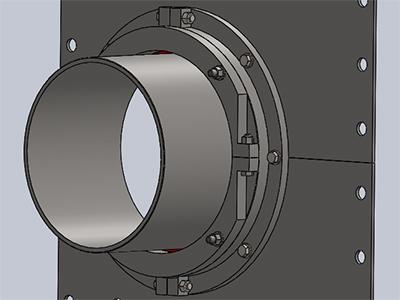

The large end of center shaft manufactured by the original design company was sealed with packing. Because of the large center shaft diameter, diameter, the gap between the packing gland and the center shaft was only 0.5 mm. When the center shaft rotated, the packing and the center shaft, the packing gland and the main shaft were not in the same center: the packing rotated together with the center shaft, and the packing gland contacted with the center shaft, resulting in a severely worn center shaft, a deformed gland, and a high rate of pulp leakage. The sealing portion of the center shaft also needed to be repaired to its original size.

Solutions

In order to protect the center shaft, Hengtai’s design team redesigned the center shaft sealing according to the design defects of the original company, replaced the packing seal with a high wear-resistant polymer material, and expanded the gap between the gland and the center shaft to 5 mm. This new structure solved the center shaft’s sealing problem and protected the center shaft’s sealing surface. After this, there will be no gland deformation or pulp leakage in the future.

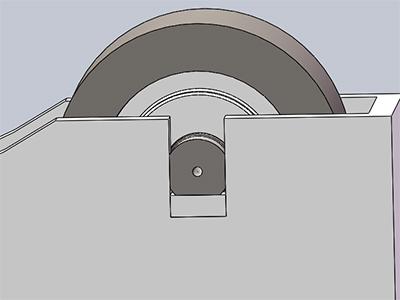

Figure of high wear-resistant polymer material

Sectional view of gland, seal and center shaft

According to the customer’s location, it takes only 2 days to replace the entire seal, including the disassembly process of removing the old ones. This reduces the downtime.

Entire seal structureProblems

The center shaft roller was also defective, and could not move up or down. This made it easy for water to get into the roller, and the roller bearing was prone to rust. When the bearing became rusted, it would become stuck and not rotate. After long term operation and wear and tear, the center shaft sunk, causing pulp leakage, the center shaft roller shifted, and caused the sector plate to scratch the tank body and damage the filter cloth and sectors.

Solutions

According to the customer’s actual situation, Hengtai optimized the design based on the original structure, and modified the structure of the roller to adjustable, so that the height of the roller can be adjusted up and down once worn to prevent the center shaft from sinking and rolling so as to to protect the sectors and mesh sreen and improve the reliability of the equipment.

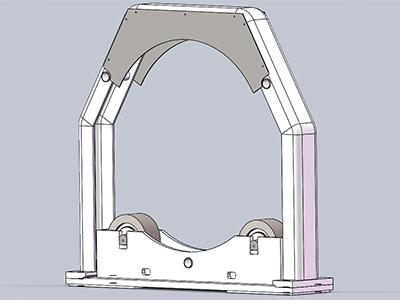

New structure of roller

Adjustable roller

Problems

The original sector seals were ordinary rubber seals. When the joint was loose, the seal easily failed. Simultaneously, after long term usage, the seal was severely deformed, causing the fiber and filler to leak away from the seal.

Solutions

Replacement of the sector seal is shown in the following figure. This new seal is not easy to deform, and is extremely durable, meaning it can be used repeatedly and has an outstanding sealing effect. Even if the bolt is loose, it will still seal. Numerous customers have achieved good results by using our sector seals.

Problems

The washdown pipe manifold in the cleaning system was attached through welding, splicing, flange connection and other connection methods. When problems arise, worker safety is significantly less. A number of sectors were seriously damaged and could not be used again.

Solutions

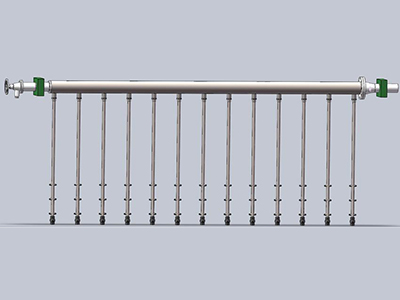

We suggested that the entire cleaning system should be modified as soon as possible, replacing the original washdown pipe manifold with one inch of pipe connected through a thread form connection instead of the original connection methods. This also ensured an easier later replacement.

The connection between the washdown pipe manifold and the main pipe

Cleaning system

The new cleaning system structure was equipped with a brush.

The internal structure of the new cleaning system

This structure greatly reduced the labor intensity of the staff, enhanced the reliability of the equipment, and reduced the maintenance cost of the equipment.

The defects of the original cake discharge systemThe main problem of the cake discharge system was that the cake discharging branch pipe was easy to run off, which was not conducive to cake discharge. Hengtai’s cake discharge system solved this problem, and the spray nozzle used was a self-cleaning spray nozzle. The pulp cake could thus be smoothly discharged, and it was easy and convenient to dredge the blocking spray nozzle.

USA - Choose Country

USA - Choose Country