- Home

- Filter Revamping and Upgrading

- Customers we served

Hengtai was founded in 2002 and has provided disc filter services for hundreds of companies throughout China and the rest of the world. Here are some examples.

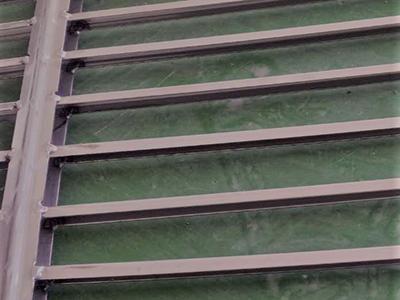

During the processing of the disc filter for Nine Dragons Paper Group, the processing capacity and processing effect were not up to standard. Therefore, they asked our company for repair and modification and technical support. The sectors were damaged in varying degrees. The mesh screen was damaged seriously. The effect of cake discharge system and cleaning system were not good. And the mesh screen was plugged badly.

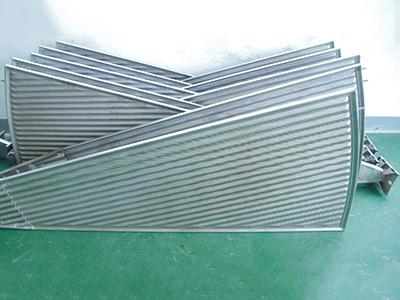

The original sector grid is a U-shaped structure made of 1 mm stainless steel, which displays weak rigidity. In order to increase the rigidity of the sector grid, we apply other structures of sector grid by using flat steel (3×14 mm) welded with the φ3 round bar steel, which greatly improved the rigidity of sector grid.

The rotary disc filter sectors were severely deformed, resulting in serious loss of paper fiber. Hengtai redesigned the sector for customers. The new sectors were made of SS316L, and the rigidity and strength were greatly improved compared to the original structure, thus the reliability of the filtration system is greatly improved.

The customer’s disc filter used a sector covered with a filter cloth. The filter cloth kept causing problems, and maintenance costs were high. According to customer requirements, we redesigned a non-filter cloth sector. Because there was no filter cloth needed, maintenance costs were reduced.

From the on-site inspection, there was a great deal of dislocation visible to the naked eye between the sector bottom and the sector base. After a careful analysis by the technical team, the conclusion was the pulp leakage was caused by serious design defects at the interface between the sector and the sector base.

USA - Choose Country

USA - Choose Country